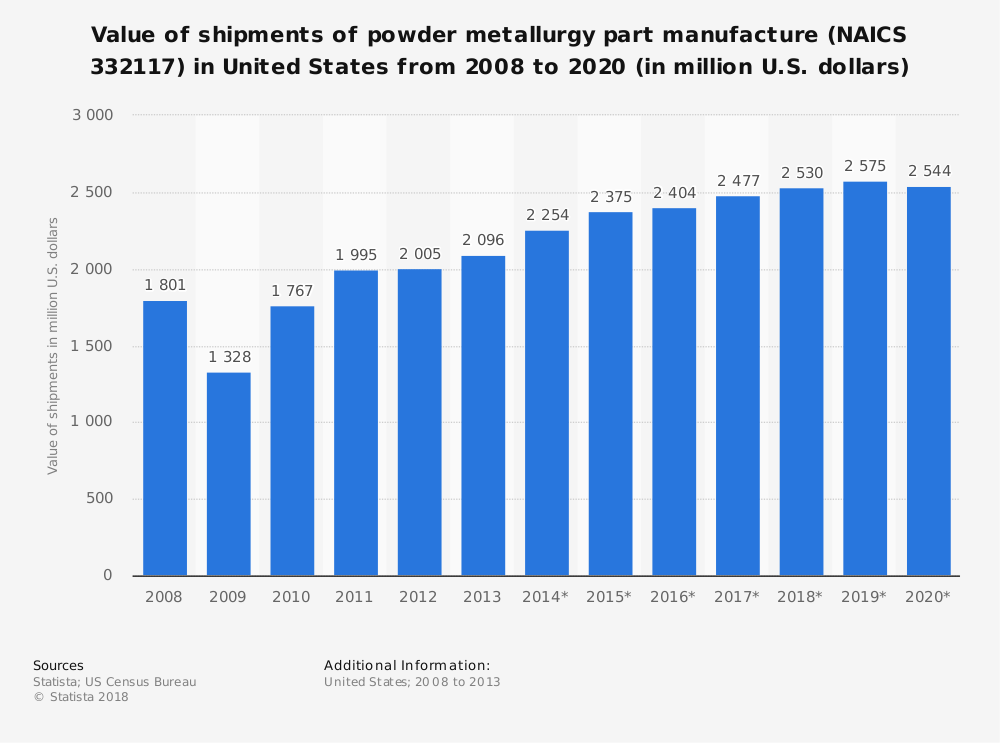

Powder metallurgy involves the production and working of metals as a fine powder. These powders can then be pressed and sintered to form specific objects. Several industries take advantage of this unique technology, creating an industry that is valued at $6 billion as of 2013 figures.

There are many advantages which come with the use of powdered metals. It is available at a price that is reasonable, can be used in a variety of industries, and the forging process makes the metal products just as strong as if they had been manufactured and refined using traditional methods.

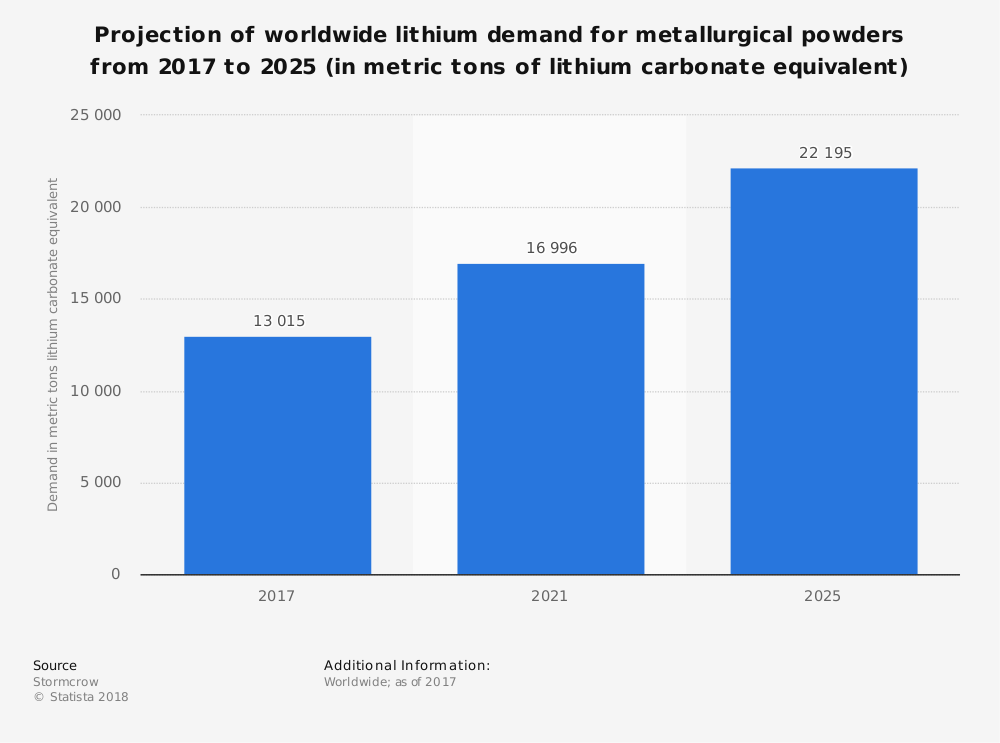

Since 2001, the powder metallurgy industry has seen annual growth rates as high as 11%. Legislation to improve fuel efficiency in vehicles is a driving force for development. With the corporate average fuel economy goal rising to 54.4 miles per gallon in 2025, the ferrous PM industry will see challenges like never before.

Important Powder Metallurgy Industry Statistics

#1. Ferrous powder is the most common product used within the powder metallurgy industry. It currently holds an 80% share of the market. (Materials Today)

#2. Powder metallurgy will typically use over 97% of the starting raw materials in the finished component that is manufactured, which allows the industry to be recognized as a green technology. (Metal Powder Industries Federation)

#3. Estimated sales from all sectors in North America for the industry totaled more than $7 billion in 2011. About 25,000 people are directly employed by the industry in some way. (Metal Powder Industries Federation)

#4. Most of the powder metallurgy companies in the United States are small businesses. 90% of the firms currently meet the definition of a small business according to the standards published by the U.S. government. (Metal Powder Industries Federation)

#5. 50% of the conventional sales achieved by the powder metallurgy industry come from automotive suppliers. 17% of sales are for automotive OEM. This is followed by recreational hand tools (8%), off-road vehicles (6%), and industrial motors (4%). (Metal Powder Industries Federation)

#6. The automotive industry consumes over 70% of the ferrous powder metallurgy components that the industry is able to produce. There are also more than 350 automotive component applications available, which creates over 1,000 specific pieces that are available for sale. (Metal Powder Industries Federation)

#7. Just 30 companies are involved with the powder and materials segment of the PM industry, which results in annual sales of $750 million. (Metal Powder Industries Federation)

#8. Most power metallurgy parts weigh less than 5 pounds, although a part weighing up to 35 pounds can be fabricated using conventional equipment. (Metal Powder Industries Federation)

#9. Atomization accounts for almost 70% of weight of all metal powders that are produced in North America. Iron and steel account for 80% of the weight of all metal powders that are produced each year.

#10. Besides iron and steel, aluminum is the most important metal powder that is produced (9%), followed by copper and related alloys (5%) and nickel (2%). All other metals combine to be responsible for just 4% of metal powder production. (EPRI Center for Materials Production)

#11. 60% of all tantalum powder that is produced by the PM industry is used for capacitors in telecommunications, electronics, and cell phones. (EPRI Center for Materials Production)

#12. About 2 million pounds of iron powder from the powder metallurgy industry is used each year to create cereal products that are enriched with iron. (EPRI Center for Materials Production)

#13. 30% of the value that comes from U.S. metal powder shipments comes from iron and steel. (EPRI Center for Materials Production)

#14. The annual global production of metal powders exceeds 700,000 tons each year. (Metal Powder Industries Federation)

#15. Powder particles for this industry are specific in shape, ranging from 0.1 to 1,000 micrometers. Most particles are similar in size to the diameter of a human hair, or 200 micrometers or less. (Metal Powder Industries Federation)

#16. The average vehicle manufactured in the United States contains 45 pounds of parts that were manufactured by the powder metallurgy industry. An estimated 850 million hot-forged connecting rods have been made for vehicles produced in Europe, Japan, and the United States.

#17. A commercial aircraft engine might contain as much as 4,400 pounds of superalloy extruded forgings. (Metal Powder Industries Federation)

#18. In 2016, about 497,000 short tons of metal powder shipments were made in North America, a figure that was about 10,000 short tons lower than the year before. Stainless steel and tungsten carbide shipments saw strong growth as a segment, despite the overall shortfall of the industry itself. (Metal Powder Industries Federation)

Powder Metallurgy Industry Trends and Analysis

Increasing demand levels from the Asia-Pacific region have helped to fuel growth in this industry in recent years. Automobile demands are rising rapidly, along with aerospace and heavy industry segments, to create a strong potential for growth.

With that potential, the powder metallurgy industry is forecast to grow at an average rate of 6% over the next 5-year period. As various industries continue to evolve and innovate, this growth rate could be even higher.

Much of this growth will depend upon the health of the automotive industry and whatever standards are used to govern production. If the automotive industry hits a rough patch, the powder metallurgy industry will soon follow. If trends continue as they are, however, this industry should continue seeing its stable growth pattern that has been in place over the past decade.

Although millions of people visit Brandon's blog each month, his path to success was not easy. Go here to read his incredible story, "From Disabled and $500k in Debt to a Pro Blogger with 5 Million Monthly Visitors." If you want to send Brandon a quick message, then visit his contact page here.