A special thanks to CompanyFolders.com for designing this great infographic. The original infographic can be found here.

Which Printing Process Is Right For You?

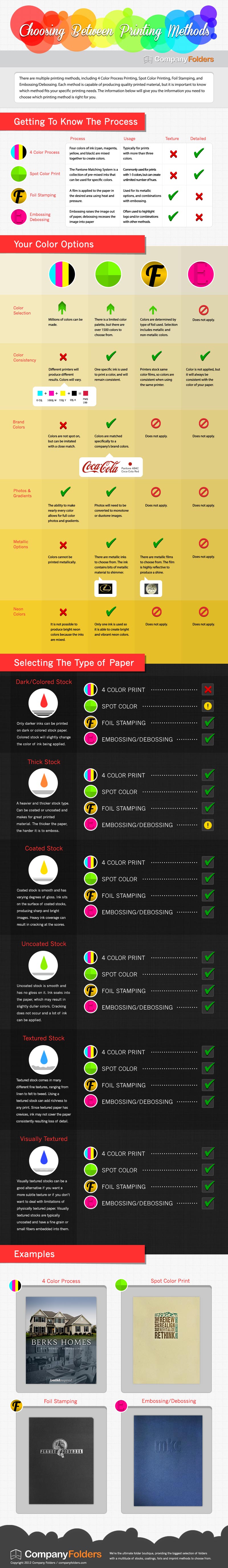

With today’s technology, creating beautiful marketing materials can happen in-house with the right combination of materials and the right printing process. The problem that so many marketers have is that they choose the wrong printing process to meet their needs because they are using incompatible materials for that process. You really can make the best first impression at an affordable cost… but which printing process is right for you?

There Are Four Processes Available

In color printing, there are four basic types of printing processes available to you:

• 4 Color.

• Spot Color.

• Foil Stamping.

• Embossing/Debossing.

These printing types are then able to be used on different types of paper stock to create the materials that you need. Let’s take a look at these printing processes in an in-depth way.

4 Color Printing Is For a Massive Impression

With 4 color printing, there are literally millions of colors available to your marketing materials. This creates a clean, crisp image that is perfect for image based items. Not every color may be perfect, but a reasonable imitation is often created. 4 color printing is often the gold standard because with the exception of dark or colored paper stock, it creates a favorable first impression.

Spot Color Adds Specificity To an Image

If you want that specific color for your branding, then you need spot color printing. You still get over 1,500 color variations from which to choose so you still aren’t completely limited in what you can do. Some photography may need to be converted, but the upside is that spot color printing allows for metallic and neon inks to be used in a presentation. As with 4 color printing, spot color printing works well on everything except dark or colored paper stock.

Foil Stamping For That Added Touch of Class

In foil stamping, you get to choose the specific color that is used. The printer will then print a foil film on top of the paper. Heat is then applied to the foil to create the permanent stamping effect. Metallic options are solely available in this printing process, so it is often done for official seals and logos. The benefit of using foil stamping is that it is a viable option on every type of paper stock.

Embossing or Debossing For Texture

Embossing helps to create raised text or images, while debossing recesses the text or images. This is most often done to put emphasis on a logo or branding image and is used in combination with the other printing methods. There is no color applied during this process, which makes it perfect for everything except thick paper stock.

Knowing what works and what doesn’t work when printing out your marketing materials will help you create the right items the first time around. Create the best first impression possible today with your selected printing process!

Although millions of people visit Brandon's blog each month, his path to success was not easy. Go here to read his incredible story, "From Disabled and $500k in Debt to a Pro Blogger with 5 Million Monthly Visitors." If you want to send Brandon a quick message, then visit his contact page here.

Comments are closed.