Polypropylene was first discovered in the 1950s by Italian scientists. Since its discovery, this plastic has become one of the world’s most versatile products. Just about everyone has something made from polypropylene in their home right now. As of 2016, the production of polypropylene in China was some 20.2 million tons. Demand in the market reached USD 105.46 billion in 2016, growing at a rate of 6.21% compounded annually.

Interesting Polypropylene Industry Statistics

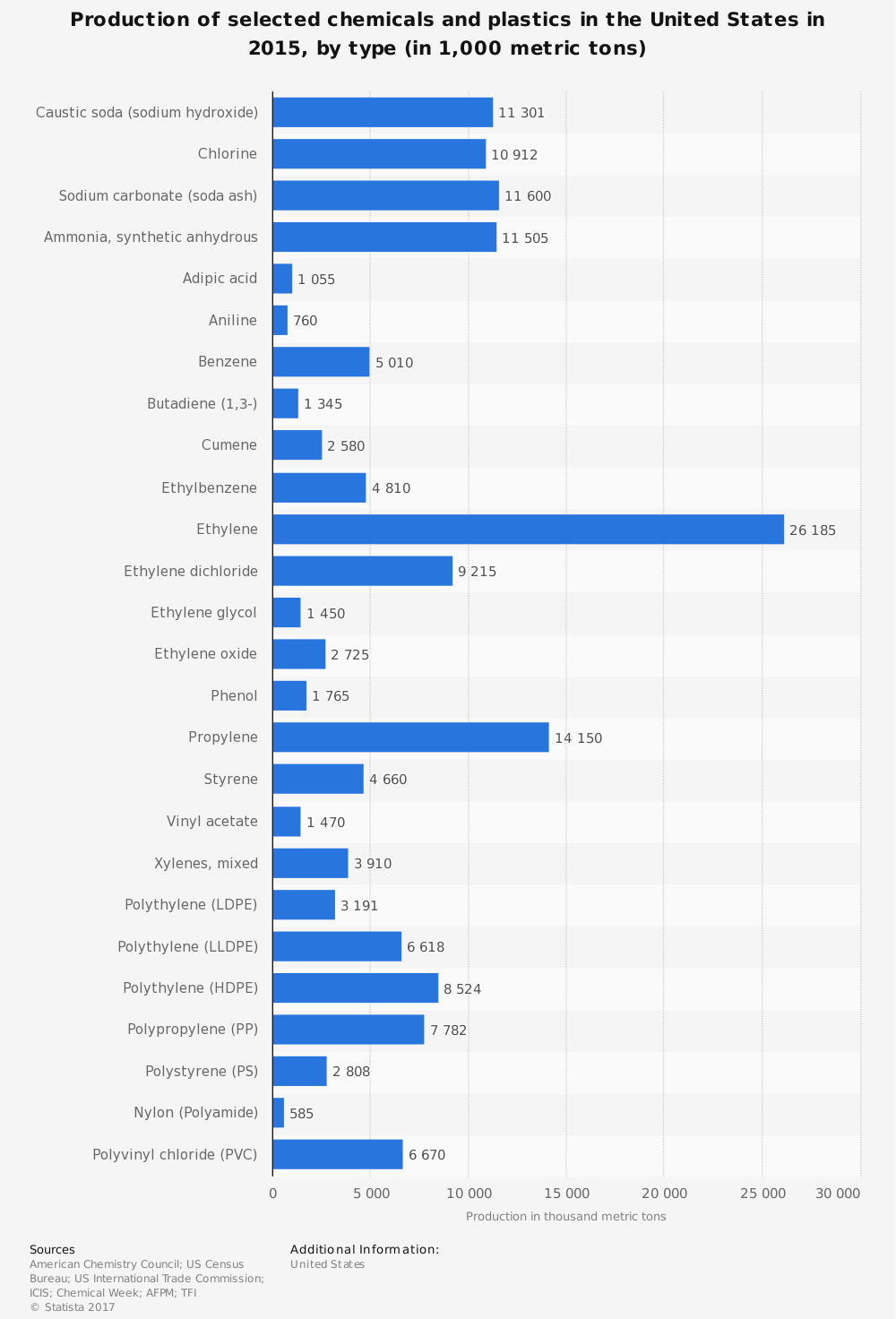

#1. The production of plastic resins in the United States totaled 7.3 billion pounds in December 2017. That was an increase of 7.7% from the year before and brought total 2017 production in the U.S. to 80.1 billion pounds. (American Chemistry Council)

#2. Sales of major plastic resins from U.S. producers totaled 6.6 billion pounds in December 2017, which was a decrease of 5.2% from the year before. For the whole of 2017, 79.5 billion pounds of plastic resins were sold, which represented a 0.2% decrease from 2016 figures. (American Chemistry Council)

#3. More than 95% of the car batteries in the United States are recycled to recover the metals contained in the battery and the polypropylene used to manufacture it. (Plastics Make It Possible)

#4. The current global demand for polypropylene creates an annual market for this plastic that can be as high as 45 million metric tons. Forecasts place total demand at 62 million metric tons by the year 2020. (Creative Mechanisms)

#5. The packaging industry is the largest consumer of polypropylene products, accounting for about 30% of the total demand that is seen globally year after year. (Creative Mechanisms)

#6. Equipment manufacturing and electrical industry uses make up 13% each of the total overall polypropylene demand that is seen in the world today. Household appliances and automotive applications make up 10% each, while construction materials are 5% of the total industry demand. (Creative Mechanisms)

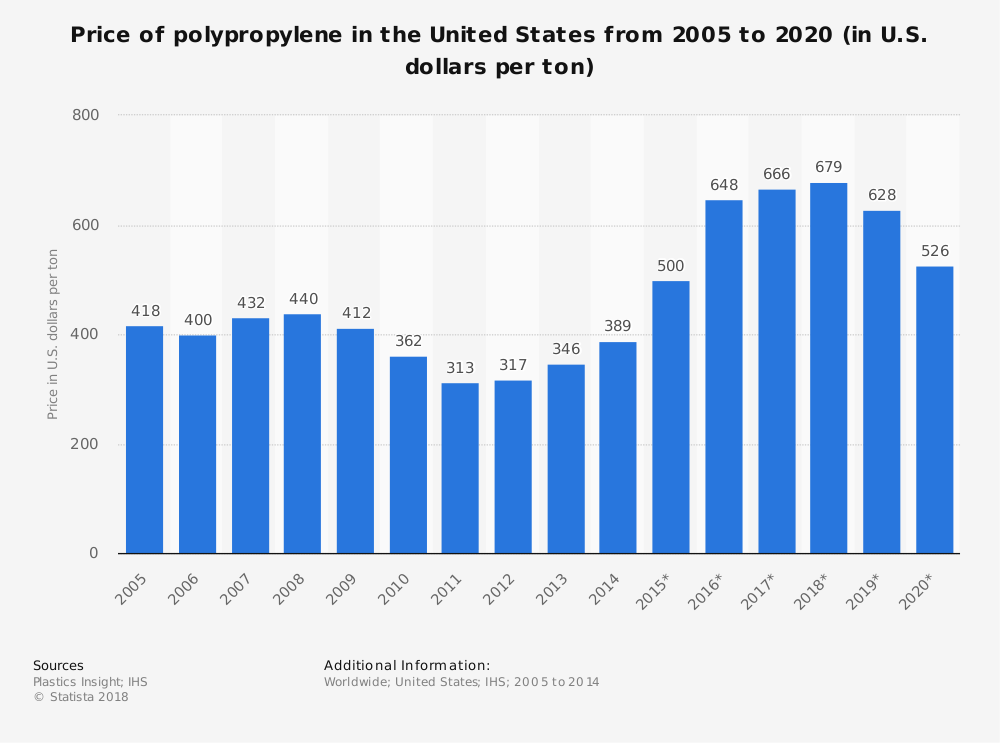

#7. In 2014, the price of polypropylene in the United States was $389 per ton. By 2020, the price is forecast to rise to $526 per ton. (Statista)

#8. The estimated global polypropylene demand CAGRs are 4.4% through 2020. This followed a CAGR of 4.6% from 2000-2015. (HMC Polymers)

#9. The estimated global GDP growth of polypropylene is forecast to be 3.2% through 2020. Short-term forecasts have been reduced, however, by more than half a percentage point because of lower oil prices, uncertainty about the Chinese economy, and other petroleum production factors. (HMC Polymers)

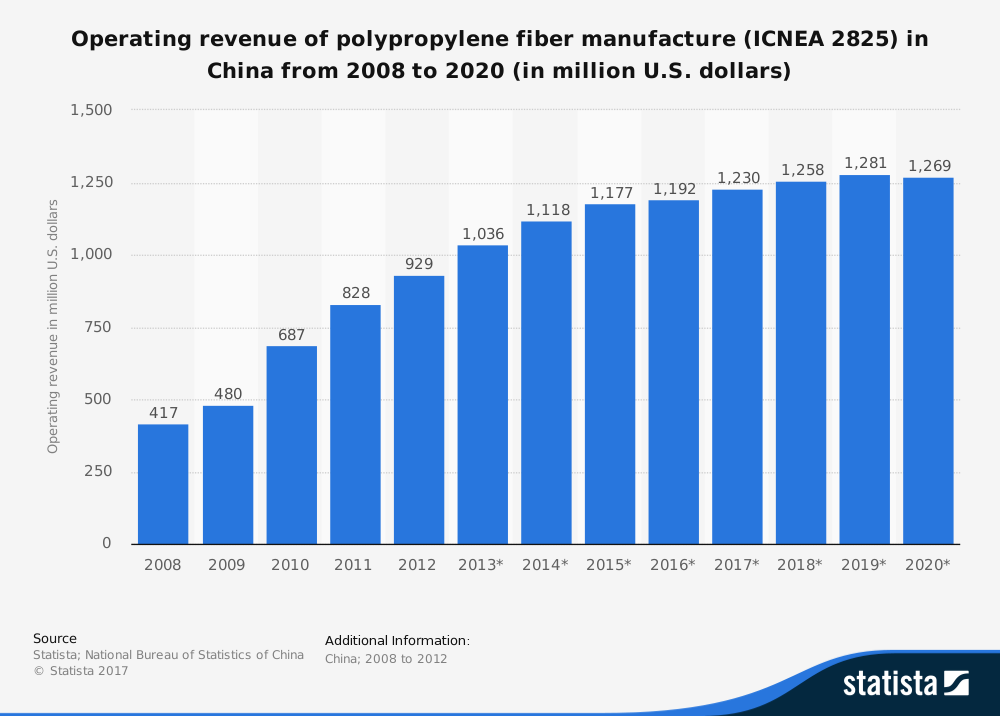

#10. Growth in the polypropylene industry tends to be dependent upon what occurs in China. Total global capacity is set to achieve 5 million tons per year by 2020, but total global demand is only forecast to be between 3.5 million and 4 million tons. (HMC Polymers)

#11. China consumed a record amount of polypropylene in 2014, reaching nearly 2.5 million tons. The rest of the world had a demand of about 1 million tons. (HMC Polymers)

#12. China, North America, and Western Europe are net exporters of polypropylene. China is also the world’s largest net importer of polypropylene each year, despite its large local production capacities. (HMC Polymers)

#13. Low-cost production in the Middle East makes it the most dominant region for polypropylene production and forecasts do not expect this position to change any before 2020. (HMC Polymers)

#14. Outside of China, Asia still has high growth opportunities for the polypropylene industry. About 4.4 million tons of polypropylene was consumed in the last year of data tracking in Asia, with Chinese figures excluded. Indonesia consumed 32% of this amount, while Thailand consumed 29% of it, and Vietnam consumed 21%. (HMC Polymers)

#15. The potential market deficits for the polypropylene industry in Asia are quite large. Demand is forecast to be 1.2 million metric tons short in Indonesia by 2025. The shortage in Vietnam is forecast to be 600,000 metric tons over the same period. There is even a 1.3 million metric ton shortage for the content as a whole, with Chinese figures excluded. (HMC Polymers)

#16. China is forecast to account for about 65% of the total incremental demand expected in Asia over the next 5-year forecast. (HMC Polymers)

#17. Total production of polypropylene increased from 44 million tons per year in 2005 to 73 million tons per year in 2015. (HMC Polymers)

#18. In 2015, the growth of polypropylene was superior to any other form of plastic resins at 7%. PE growth was just 4%, while PET growth was 3.4%. PS resins saw a decline in overall production of 0.5%. (I.H.S. Chemical)

#19. North America took steps toward its cyclical peak in 2015, increasing spreads over monomer by 20cpp that year. (I.H.S. Chemical)

#20. Global operating rates for the polypropylene industry in 2015 were at 88%, which exceeded the expectations of 84% operating rates that had been forecast. (I.H.S. Chemical)

#21. Lower prices and an emphasis on recycling saw demand in China rise by over 700,000 metric tons for plastic resins. (I.H.S. Chemical)

#22. Polypropylene is the preferred resin in almost every region of the world in terms of pricing. In North America, the PP to PE price ration in 2017 achieved record levels of nearly 1.9. In comparison, the price ration in 2015 was below 1.0 with the same comparison. (I.H.S. Chemical)

#23. Margins for the polypropylene industry are forecast to decline from record levels in 2017 that were nearly $0.30 per pound. The expectation in 2020 is for the industry to settle in around $0.15 per pound in North America. (I.H.S. Chemical)

Polypropylene Industry Trends and Analysis

Unless trends shift dramatically, the polypropylene industry will continue to provide a strong boost to the global economy. Although sales figures are down somewhat in 2017 figures, a stronger economy in Asia and Europe in the next 5 years creates a forecast of strong growth from a global perspective.

It’s versatility to cross numerous industries to provide products is what gives the polypropylene industry such a strong foundation. From surgical components to halogen cabling, polypropylene is the top choice.

You can tell if you’re using a product that is made from polypropylene in the United States because of its resin code. It will have the recycling symbol stamped onto the product with a 5 in the center.

Although millions of people visit Brandon's blog each month, his path to success was not easy. Go here to read his incredible story, "From Disabled and $500k in Debt to a Pro Blogger with 5 Million Monthly Visitors." If you want to send Brandon a quick message, then visit his contact page here.